Software integrations increase the profitability of investments in prefabrication production systems

Innomac and Vertex work closely together to ensure the productivity of customers’ manufacturing equipment investments. This is best achieved when software issues are also taken into account already in the planning phase of the purchasing process.

Founded in 2010, Innomac Oy offers its customers manufacturing equipment, devices, and production line solutions related to wood, aluminium, and plastic processing, as well as to surface treatment and recycling technology. The offering also includes expert installation, maintenance, and spare parts services, user training, and various project services.

Product manager Kai Nurminen is responsible for the CNC controlled production systems at Innomac. The company’s product portfolio includes several top machinery suppliers in their field, who offer solutions for the processing of different materials.

“In addition to the building industry, our customers include all kinds of other players who need solutions for working with wood and wood-like materials, plastic, aluminium, composites, and other advanced materials, as well as for surface treatment and recycling materials handling,” says Nurminen.

“We serve a wide variety of customer needs. Where one person is looking for, for example, an entire through-feed drill line for their production, some other customer may simply need, for example, a single planer. In terms of turnover, CNC machining centres form some of our most significant product groups.”

Software integration is a crucial factor for efficient production

Programs for CNC machines and various design and production control software suites are an integral part of modern production. They improve work accuracy and efficiency at different stages and prevent human errors, which in turn saves time, effort, and money in production.

That is why it is important to bring up software integrations right away at the beginning of the procurement project. This promotes the smoothness of commissioning and operation of a new machine or production line, as well as the profitability of the whole investment.

“Delivery times for production systems vary from a few months to a year or even a little longer. If the delivery is scheduled to one month from now, and software integrations have not been dealt with, we are already running behind,” says Nurminen.

Innomac works closely with Vertex to ensure that the customer will get functioning solutions also on the software side. At Vertex, these issues are promoted by people like Jukka Haho, who works as a product manager in products serving the construction industry and mainly operates in sales and product development.

“The client should contact us already in the planning phase of production line investment. There are many things involved in the setup phase, and the final project phase always involves various hassles on the equipment side. That is why it is best to take care of the issues that can be done in advance, says Haho.

He assures that Vertex can provide qualified expert help for these needs, and the cooperation does not even require that much time or effort from the clients at that stage.

“When we see what the client is purchasing, we can tell you what it means and requires in terms of software. The essential thing is to know in what format data should be entered into the manufacturing equipment and what the programs must be able to do. This is of course influenced by the kind of products in question – how they are designed and sold. Whether the product is, for example, completely standard or does it need to be modifiable to different customer requirements.”

When the client approaches us well in advance, they also get maximum benefit from the cooperation between Innomac and Vertex. This way we will have time to go through the customer’s purchase together from the equipment and software perspectives and ensure the best possible total functionality.

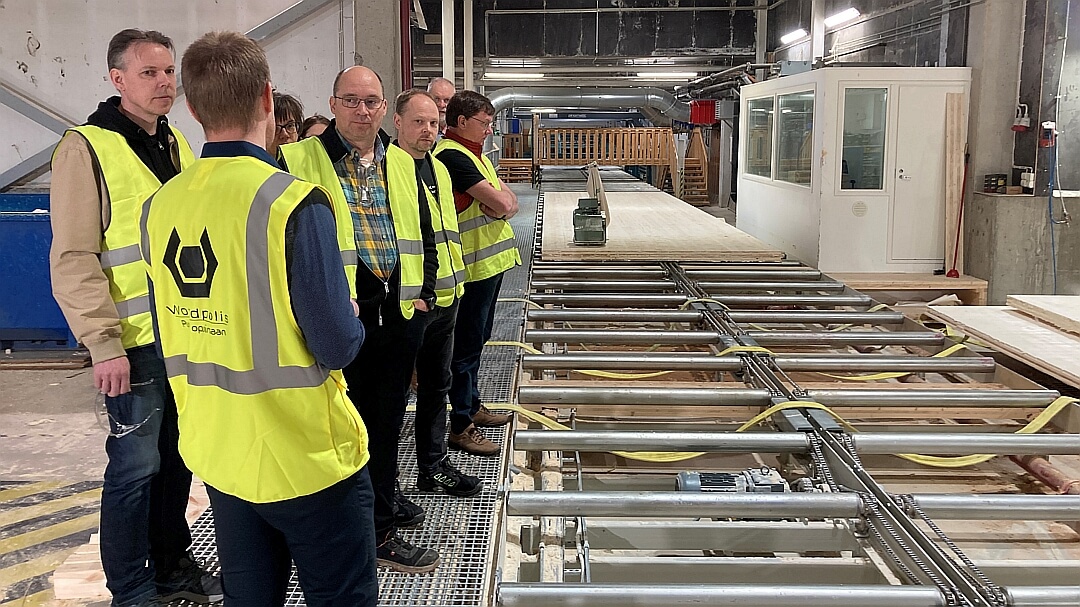

Vertex staff learning about CLT production at Crosslam‘s factory in Kuhmo, Finland.

Software integration is an essential part of the entire investment

The most important reason to act early enough in software matters is, of course, the profitability of the prefabrication production system investment. Software integration is one of the most significant factors of the project. If not enough time is allocated for this, there may be problems and delays in the system setup, and production may run slower than expected or even stop completely.

“Software integration speeds up the process, prevents human errors and certainly pays for itself. But if things are not done in advance, additional costs and double work are incurred from solving problems, and the investment repayment period becomes much much longer,” reminds Nurminen.

“During the setup phase of a production system, initial downtime can occur for many reasons. However, the most annoying and pointless thing is if the problems are caused by issues that could have been tackled in advance. In the worst case, the disadvantages can be multiplied by the fact that the client’s production problems also affect deliveries and customer satisfaction,” Haho affirms.

Seamless cooperation for the benefit of the client

Innomac’s first joint project with Vertex was launched in 2017. That project involved the delivery of CNC-controlled drilling machines, for which Vertex provided control software.

“From our point of view, it was great that when clients used Vertex’s programs to model their products, they automatically produced corresponding working plans. The solutions started working quickly without too much time-consuming temporary-stage work,” says Nurminen.

Innomac’s and Vertex’s customer bases are connected in many ways, so it has been natural for the companies to join forces to always offer the customer the best overall solution. According to Nurminen, cooperation has been uncomplicated and smooth in every respect.

“Vertex Systems is a well-known and reputable operator that offers high-quality software solutions. It has also always been easy to talk with their professionals and figure things out as needed. We usually find common ground quickly even with difficult issues.”

Jukka Haho confirms that the companies’ cooperation aims at a functioning whole:

“After all, we collaborate to find solutions for our customers. They choose the systems they use, and we then strive to ensure that the whole works in the best possible way.”

The significance and potential of software suites are constantly expanding

Technology is developing at a fast pace, which further increases the importance of the software side in ensuring productivity for manufacturing equipment.

“Software has played a large role in numerically controlled machines for a long time. Now they are starting to connect more and more often to other devices through various IoT environments. I believe that in the future, in the delivery of individual devices, there will be even more talk about integrations with software and third-party robot or automation solutions,” reflects Nurminen.

According to him, customers are already very much aware of the importance of software and want to find new ways to get added value to their production.

“Customers already know how to import geometries from plans to the equipment via existing interfaces, or even to automatically create CNC programs. Our task is, of course, to find ways to realise these objectives.”

“The customer’s new production system usually has a program that reads the numerical data it receives. When we know what kind of interface we are dealing with, we can transfer the manufacturing data to production in the desired format,” assures Haho.

“In a way, the customer is producing a virtual twin or a model that contains all the data and manufacturing information. The role of the software is key here, especially when your production is unique. An intelligent 3D model contains all the necessary information even if you make changes to the original design.“

“We welcome new challenges with open arms!”

Kai Nurminen underlines that for Innomac, customer work is not just delivering manufacturing equipment, but the goal is to ensure the entire project is in cooperation with the software supplier.

“For us, a customership is a mental commitment. That’s why we do everything we can to make the software side a success as well, and if necessary, we clarify related issues coming from our clients. We want our customers to succeed, and software, automation, and robotics integrations are solutions that boost both their design work and the entire production,” Nurminen states.

“This is important especially because construction industry is facing significant challenges. The shortage of labour has been hindering operators of all sizes for a long time and could get worse still. Automating design and production helps to operate better and more productively with existing resources, but at the same time it can increase the industry’s attractiveness and raise interest among young people.”

Therefore, Nurminen urges customers to boldly challenge Innomac and Vertex to solve their various production needs: “Many times there already exist ready-made solutions for the customer’s expectations – we just need to hear these wishes in good time.”

Related Stories

Cold-formed steel design-to-factory automation with Vertex BD

To fully realize the benefits of offsite manufacturing and modular construction, companies need a digital workflow that links the design office directly to fabrication.

Why Vertex is the leading CAD construction software

Best 3D construction software for professionals The construction industry is evolving rapidly, with factory-built construction gaining popularity due to its efficiency and precision. Companies that manufacture building components - such as walls, floors, and entire...

Best 3D construction software for professionals

Best 3D construction software for professionals 3D construction software has become a cornerstone of modern building projects, fundamentally transforming traditional construction practices. By enabling architects, engineers, and builders to create highly detailed,...