BIM Technology Blog

Read how to improve safety, efficiency and speed in prefabrication, offsite and modular construction.

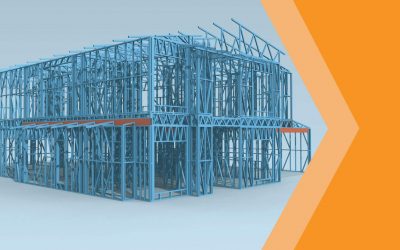

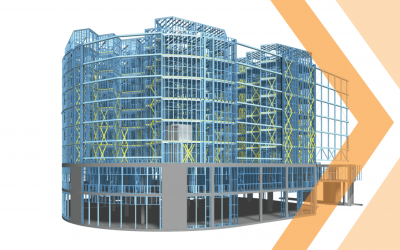

Best 3D construction software for professionals

Best 3D construction software for professionals 3D construction software has become a cornerstone of modern building projects, fundamentally transforming traditional construction practices. By enabling architects, engineers, and builders to create highly detailed,...

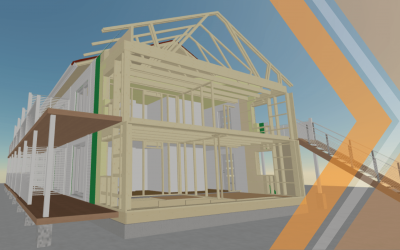

Leading construction design software for professionals

Leading construction design software for professionals In the ever-evolving construction industry, construction design software has become indispensable for streamlining workflows, enhancing accuracy, and improving collaboration. Among the available options, Vertex BD...

What is modular building design? – Unlock efficiency and precision

To fully unlock the potential of modular building design, it’s essential to utilize advanced tools that streamline the process from design to construction. While modular construction already offers significant advantages like faster timelines and cost savings, a tool like Vertex BD takes it further by integrating design and manufacturing into one seamless platform.

What is BIM Software? 5 tips to leverage it in your business

Learn what BIM software is and how to leverage it in construction with 5 tips, including Vertex BD’s benefits for home builders.

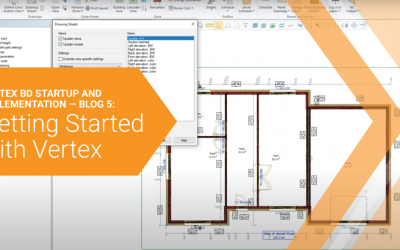

Vertex BD Startup and Implementation — Blog 5: Getting Started with Vertex

In this blog we share a few tips to help new customers get off to a smooth start folding Vertex into their daily workflows, where the most value can be realized.

Vertex BD Startup and Implementation — Blog 4: Sectors and Use Cases Where Vertex BD Excels

Building information modeling (BIM) software is revolutionizing the architecture, engineering, and construction (AEC) industry on a similar scale, and Vertex BD’s BIM platform offers distinct advantages to building owners, designers, and contractors across every sector of the industry.

How Vertex BD Helps Designers, Builders, and Owners

The risk and complexity increase when organizations implement digital transformation in their core operations and technical functions. This is the case for property owners and architecture, engineering, and construction (AEC) firms selecting and implementing a building information modeling (BIM) software platform.

What Can BIM Do for Your Company?

In this blog, I introduce the higher-level benefits of BIM and drill down into the specific areas in which BIM technology excels.

Introduction to BIM and What It Can Do for Your Company

This blog series will walk AEC organizations and other interested parties through the decision-making process for selecting and implementing a BIM platform. I will shed some light on why so many companies are implementing BIM, and I will also highlight some of the best use cases for BIM and share some of our customers’ success stories.

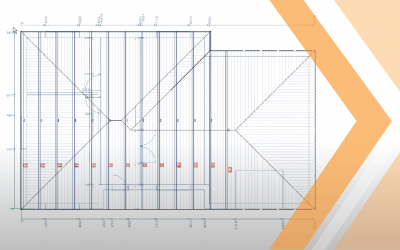

Software integrations increase the profitability of investments in prefabrication production systems

If not enough time is allocated for software integration, there may be problems and delays in the system setup, and production may run slower than expected or even stop completely.

DfMA: Why Manufacturing Is the Key to Viability — Blog 5: New Horizons for DfMA

In this final blog in my series about DfMA, I look toward the future and discuss three new technologies that will both impact the construction industry and evolve alongside it in the years and decades to come: next-generation building information modeling (BIM), artificial intelligence (AI) and production automation.

DfMA: Why Manufacturing Is the Key to Viability — Blog 4: New Principles for Scalability

Dive into our exploration of five key principles for DfMA startups to scale: economics, ecosystems, design-manufacturing alignment, automation, and execution. Learn from the past, and shape the future of DfMA.

DfMA: Why Manufacturing Is the Key to Viability — Blog 3: Katerra and Lessons Learned

The rise and fall of Katerra, which burned through more than $2 billion in just six years, is the most discussed story related to DfMA in decades.

DfMA: Why Manufacturing Is the Key to Viability — Blog 2: Why DfMA?

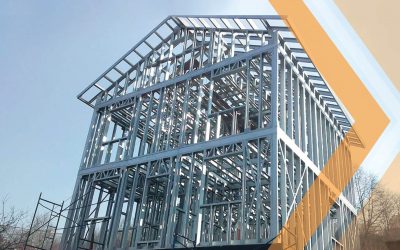

Design for manufacturing and assembly (DfMA) is a revolutionary approach to construction that is poised to reshape the economics of the global construction industry in the coming years.

DfMA: Why Manufacturing Is the Key to Viability – Blog 1: Introduction to DfMA and Its Core Principles

What would you say is the difference between manufacturing and construction? There are many ways to approach this question, but the simplest distinction is where the labor is performed. Manufacturing labor is performed in a factory, while construction labor is typically performed outdoors, in the elements. There are benefits, drawbacks, and limitations to each, and they are both essential for every construction project.

The Facts About Off-site Construction — Blog 5: Cross-laminated Timber

CLT construction expands upon many of the benefits of off-site construction in general, such as reduced waste, higher levels of quality control, and accelerated building timelines. This approach also offers several unique benefits.

The Facts About Off-site Construction — Blog 4: Hybrid Construction Systems

Structures that utilize both panelized and modular construction are known as hybrid systems, and they provide owners and designers with the ultimate range of flexibility. Let’s discuss hybrid systems and how they’re changing off-site construction.

The Facts About Off-site Construction — Blog 3: Volumetric Modular Construction

Cost savings are a major benefit of volumetric modular construction projects. This approach involves manufacturing 3D modules off-site and then arranging and connecting them at the job site to create the finished structure.