Customer Case Studies

Learn how our clients are saving time and money with Vertex BD.

Categories: Latest Stories | Steel Framing | Wood Framing | Manufacturing Equipment

Latest Stories

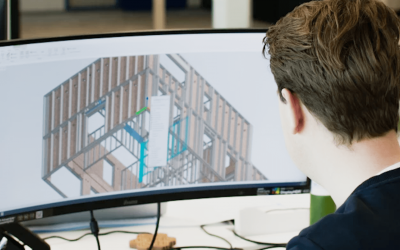

Helena Lidelöw: Steering VBC to global success with Vertex BD software

VBC grows with a core strategy centred on customisation and flexibility in Vertex BD, guided by Helena Lidelöw.

Building Better with Steel: Sweelco Is Using Tech and Steel to Revolutionize Construction

By using advanced BIM software like Vertex BD, Sweelco enhances the construction experience for its clients by making the design process more precise and efficient, ensuring high-quality results from design to production.

The three questions that shaped Ecohuis success in modular

Ecohuis, the leader in the Belgian modular home market, has shaped their success by focusing on three critical questions.

Leveraging automation: Vertex BD’s, Randek’s and Arcabo’s partnership offers unparalleled benefits

Arcabo has revolutionized home-building through strategic partnerships with Vertex Systems and Randek, leveraging automation to offer high-quality buildings at various price points.

MYT Framing Solutions

MYT Framing Solutions achieves seamless collaboration and accelerated project completion with Vertex BD software. By supplying 100 tonnes of steel frames for the Norwood mixed development project, the company demonstrates its expertise in handling complex designs and delivering lightweight frames for large-scale projects.

Holder Homes

Holder Homes, a leading residential builder in Sydney, Australia, has embraced modular building with the help of Vertex BD. By producing their own timber frames and utilizing off-site construction, the company has successfully navigated supply and labor shortages caused by the Covid-19 pandemic, ensuring timely project completion and cost efficiency.

Steel Frames Direct

Steel Frames Direct was established in 2020 to provide light gauge steel framing solutions for residential, commercial and light industrial building projects. The company’s focus on customer satisfaction, and use of Vertex for efficient collaboration and communication sets them apart from their competitors.

Hawo

Hawo are a manufacturer and supplier of high-quality tiny homes and holiday houses. They are forerunners in prefabrication, basing their production in a self-developed concept of prefabricated housing.

Uniplan Group

Through computer-controlled off-site manufacturing techniques and software that improve precision and speed, Modern Methods of Construction shortens the time between design and delivery, reducing labor costs, eliminating unnecessary waste, and improving safety and quality from start to finish.

Steel Framing

Building Better with Steel: Sweelco Is Using Tech and Steel to Revolutionize Construction

By using advanced BIM software like Vertex BD, Sweelco enhances the construction experience for its clients by making the design process more precise and efficient, ensuring high-quality results from design to production.

MYT Framing Solutions

MYT Framing Solutions achieves seamless collaboration and accelerated project completion with Vertex BD software. By supplying 100 tonnes of steel frames for the Norwood mixed development project, the company demonstrates its expertise in handling complex designs and delivering lightweight frames for large-scale projects.

Steel Frames Direct

Steel Frames Direct was established in 2020 to provide light gauge steel framing solutions for residential, commercial and light industrial building projects. The company’s focus on customer satisfaction, and use of Vertex for efficient collaboration and communication sets them apart from their competitors.

Uniplan Group

Through computer-controlled off-site manufacturing techniques and software that improve precision and speed, Modern Methods of Construction shortens the time between design and delivery, reducing labor costs, eliminating unnecessary waste, and improving safety and quality from start to finish.

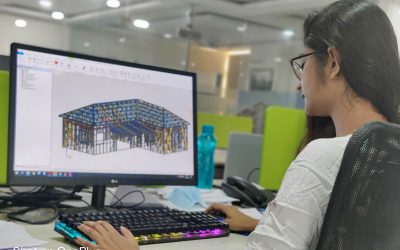

UBC

How Cold-Formed Steel + BIM Software is Changing Construction in India?

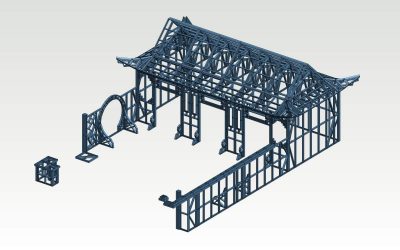

ARKEO System

Light steel framing is making its mark on the construction industry — and it’s easy to see why. One company doubling down on the benefits of the LSF construction method is ARKEO system, a French company that supplies its product to developers, contractors, architects and installers.

BATI-FABLAB by CIOA

Bringing people together with Cold-Formed Steel to solve a global lack of housing.

Civic Steel Homes

Improved communication between different parties in the construction process has decreased the turnaround on reviews, meaning they get jobs produced and on site sooner.

Jiu Tai Steel

Jiu Tai Steel builds more than 1,000 houses every year. Experience, professionalism and cost-effective production of frames is their key to success.

Cascade Manufacturing

With the ability to complete designs approximately twice as fast as before increases capacity for CFS projects and revenue. At the same time, greater speed, accuracy, and ease of working with Cascade encourages repeat business from clients.

Greater Metroplex Interiors

“Before it might take three weeks to do the layout and get all the wall panels drawn up. Now we can do the same project in roughly a week’s time.”

Excel Engineering

With design automation engineers complete designs 2-3 times faster, with more accuracy and double the amount of information for clients.

Wood Framing

Helena Lidelöw: Steering VBC to global success with Vertex BD software

VBC grows with a core strategy centred on customisation and flexibility in Vertex BD, guided by Helena Lidelöw.

The three questions that shaped Ecohuis success in modular

Ecohuis, the leader in the Belgian modular home market, has shaped their success by focusing on three critical questions.

Leveraging automation: Vertex BD’s, Randek’s and Arcabo’s partnership offers unparalleled benefits

Arcabo has revolutionized home-building through strategic partnerships with Vertex Systems and Randek, leveraging automation to offer high-quality buildings at various price points.

Holder Homes

Holder Homes, a leading residential builder in Sydney, Australia, has embraced modular building with the help of Vertex BD. By producing their own timber frames and utilizing off-site construction, the company has successfully navigated supply and labor shortages caused by the Covid-19 pandemic, ensuring timely project completion and cost efficiency.

Hawo

Hawo are a manufacturer and supplier of high-quality tiny homes and holiday houses. They are forerunners in prefabrication, basing their production in a self-developed concept of prefabricated housing.

Acetra ZWOLLE Project: Part 3

Working together with the entire design and construction team, Acetra advises the assembly of the three-story CLT structure to completion.

Acetra ZWOLLE Project: Part 2

With the help of BIM technology, the Acetra team works together with architects and contractors to create a modern design that blends seamlessly with its traditional surroundings.

Hoivarakentajat

Log as a material is sense-friendly, calming and natural. It is acoustically pleasant, balances moisture in indoor air, and its construction physics are well suited for Scandinavian climate. Timber structures enable carbon-negative construction.

ACETRA: the Zwolle Project Part 1

In construction, challenges come with the territory. But for some projects, like this three-story residential/commercial CLT structure in the Netherlands, the complications are what take the design to the next level.

Service Offsite Solutions

Service Offsite Solutions is changing the way residential framing is done by delivering a framed house, dried-in, in less than half the time it takes for traditional stick framing.

Celt

When the plans are finished in advance, manufacturing the CLT panels and assembling the components is much more cost-efficient and the entire project schedule is significantly shorter. Prefabricated construction with CLT panels is quicker, more efficient and is carried out in controlled indoor conditions from start to finish.

Design Service JK

Factory-based production of wooden houses is not unusual anymore. Nowadays, a high priority is given to the quality of indoor air and protecting the structures from getting wet during construction is a must. Cross Laminated Timber panels are manufactured indoors which also reduces the amount of on-site work.

Manufacturing Equipment

Leveraging automation: Vertex BD’s, Randek’s and Arcabo’s partnership offers unparalleled benefits

Arcabo has revolutionized home-building through strategic partnerships with Vertex Systems and Randek, leveraging automation to offer high-quality buildings at various price points.

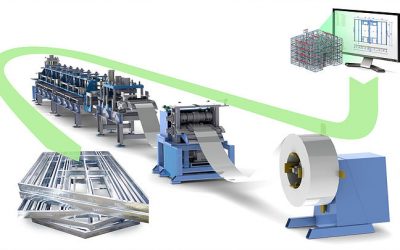

UNBAK

At UNBAK, one of the leading profile-forming machine manufacturers in the world, long-term success depends on one important element: innovation.

Arkitech

With more than 15 years of experience in the field of light steel processing, a comprehensive solution has been developed to ensure very accurate and reliable production processes. The Arkitech system guarantees lower costs than traditional construction methods.

Xiamen Xinhonghua Machinery

“New entrants now find it more convenient to learn about the whole procedure of light steel frame construction — from how to design a building using light steel frame structure design software, how to produce the light steel frames with our machine, and how to assemble them together according to drawings.”

Samesor

“By connecting the most versatile manufacturing equipment with a BIM software, builders will boost production capacity and improve speed and accuracy. Building projects will be completed faster and without mistakes.”

FrameMac

“Working with Vertex has enabled us to achieve a satisfactory share of the Chinese market. We have quickly gained market visibility and laid a good foundation for the future.”

PinnacleLGS

“Knowing various framing software in North America and Australia, we found Vertex the most suitable option for our requirements in the offering of efficient and productive design tools to our worldwide clients.”

Macring Group

“Since paper design drawings are no longer necessary when working with profiles, human errors are decreased when manufacturing details are produced automatically onto the line.”