The construction industry is undergoing a profound transformation. As owners and contractors push for faster delivery, greater sustainability, and tighter cost control, the need for purpose-built software for cold-formed steel (CFS) framing has become critical. CFS has rapidly proven itself as a leading solution for modern, high-performance building systems—but material choice alone does not secure productivity or quality.

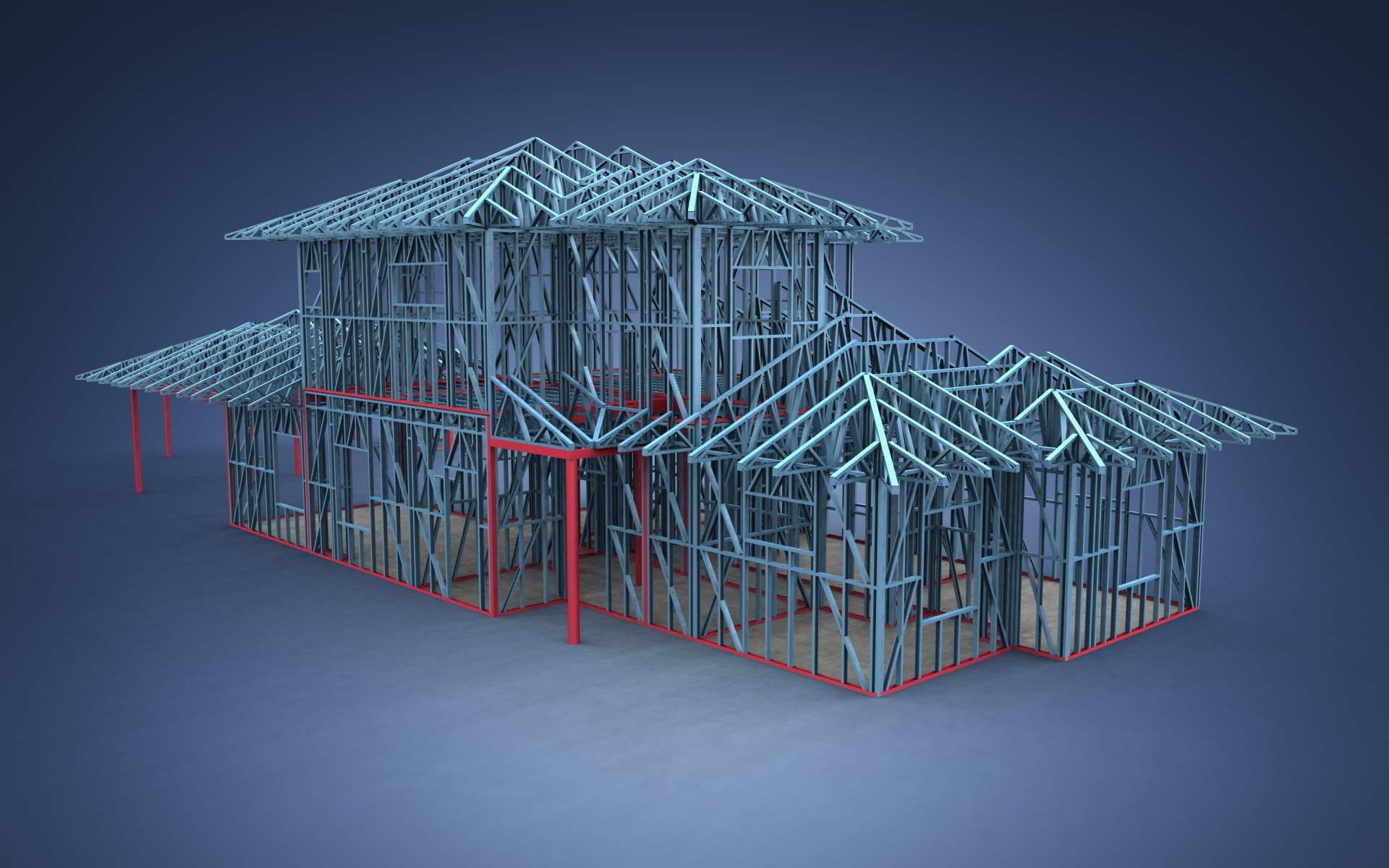

To fully realize the benefits of offsite manufacturing and modular construction, companies need a digital workflow that links the design office directly to fabrication. This requires more than generic CAD. CFS projects involve rule-based detailing, automated assembly logic, accurate manufacturing data, and change control across disciplines—capabilities that standard tools are not designed to manage.

At Vertex, we work daily with detailers, drafters, and engineers who face these challenges. That’s why a dedicated BIM solution such as Vertex BD is a decisive step toward industrializing your CFS process. Vertex BD enables end-to-end automation from design to production, reduces rework by eliminating manual data handling, and generates factory-ready outputs that accelerate manufacturing—often delivering dramatic gains in speed and reliability.

Read more about Vertex BD for cold-formed steel framing.

What is Cold-Formed Steel software?

Cold Formed Steel software is a specialized Building Information Modeling (BIM) tool designed specifically for the nuances of steel framing. Unlike generic architectural software, which treats walls as simple lines or 3D blocks, specialized software like Vertex BD understands the structural reality of the building.

It understands studs, tracks, headers, bracing, connectors, and many more. Most importantly, it understands how to translate that digital data into instructions for roll-forming machinery.

The problem with generic CAD

Many firms struggle because they try to force standard CAD tools to perform complex steel detailing. This leads to:

- Manual data entry: Typing measurements into machine controllers by hand.

- Disconnects: Architectural and detailing information is split across separate files and systems.

- Errors: Clashes between plumbing and steel frames are discovered only when the wall is being assembled.

Vertex BD solves this by streamlining the entire building process—from architectural detailing to manufacturing—in one platform.

How Vertex BD automates your workflow

The core promise of our software is simple: Produce plans up to 2X faster. We achieve this through intelligent automation that handles the repetitive “heavy lifting” of detailing, allowing your detailers to focus on complex problem-solving.

1. Automated panel & truss generation

With Vertex BD, you don’t draw every stud manually. You define your framing rules once. The software then automatically generates the framing for walls, floors, ceilings, and roofs based on your specifications.

- Need to change a window size? The framing updates automatically.

- Need to change the stud spacing? The software regenerates panels in seconds.

2. Instant documentation

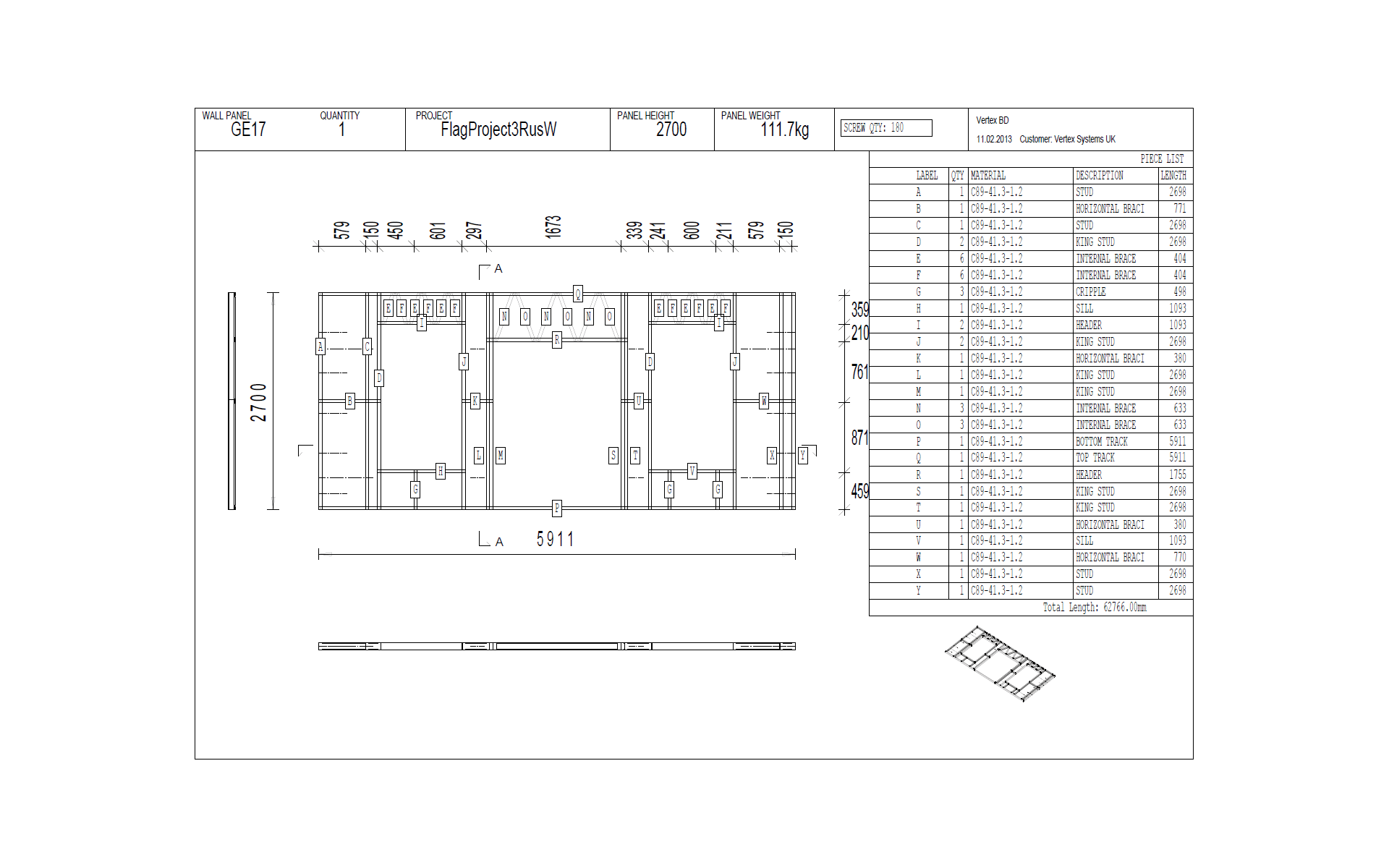

Creating shop drawings is often the biggest bottleneck in production. Vertex BD automates the generation of:

- Panel fabrication drawings

- Structural layouts

- Cutting lists

- Material reports

What used to take weeks of drafting can now be accomplished in days. As Michael Ward from GMI notes:

“Before it might take three weeks to do the layout and get all the wall panels drawn up. With Vertex BD we can do the same project in roughly a week’s time.“

The “Design-to-Production” bridge: Eliminating manufacturing errors

The true power of Cold-Formed Steel software lies in its ability to connect to production equipment. Vertex BD acts as a bridge between your design team and your manufacturing equipment.

Direct integration with roll forming machines

We support virtually all leading roll-forming machines. Once your BIM model is complete, Vertex BD creates the exact NC data required by your machinery. This data is exported directly to the equipment, bypassing the need for manual input.

Why does this matter?

- Zero Transcribing errors: You eliminate the risk of a machine operator mistyping a length or punch location.

- Millimeter precision: The profile produced by the machine is exactly the profile designed in the model.

- Reduced waste: Accurate cut lists mean you only use the steel you need.

The digital twin advantage

By utilizing a data-rich BIM model, you are essentially building a “Digital Twin” of the project before construction begins. You can visualize the structure in 3D, check for clashes, and verify connections.

Brett Smith from Queensland Steel House Frames puts it best:

“Vertex allows us to double-check every single wall or truss, as if you actually were on the site looking at the house. It stops us from making mistakes and having things sent to the site incorrectly.“

Vertex Sync allows seamless sharing to production and site

To truly industrialize construction, information must flow freely beyond the design office. Vertex Sync complements the automation of Vertex BD by serving as a secure, cloud-based hub that links your designers to the real world. It allows you to easily share 3D models and 2D drawing sets directly with the production team and the job site. Instead of relying on outdated paper prints or email attachments, factory staff and installation crews can view the latest designs on any device. By ensuring that everyone from the manufacturing floor to the construction field is looking at the same up-to-date data, Vertex Sync eliminates communication gaps and ensures the project is built exactly as designed.

Read more about Vertex Sync here.

Adaptability: The software that grows with you

In the prefabrication and modular sector, every manufacturer has its own unique processes and priorities. You should not be forced to change your building methods to suit your software; your software should adapt to you.

Vertex BD is renowned as the most customizable framing software on the market.

- Open System: We are not tied to specific material manufacturers.

- Custom Profiles: Do you use proprietary material shapes? They can be easily added to the system.

- Scalability: Whether you are building homes, commercial buildings, or multi-story modular hotels, Vertex BD scales to handle the complexity.

Conclusion: Build smarter, not just harder

The competition in the construction sector is fierce. To stay ahead, you cannot afford to rely on manual drafting and disconnected processes.

Vertex BD is more than just a drawing tool; it is a comprehensive automation platform for Cold-Formed Steel construction. By implementing Vertex BD, you are not just buying software—you are investing in:

- Speed: Faster design cycles and quicker time-to-market.

- Accuracy: A drastic reduction in onsite errors and manufacturing waste.

- Growth: The capacity to take on more complex projects without adding more staff.

Join the 18,000 professionals in 147 countries who rely on Vertex to automate their business.