UBC BIM Services & Vertex BD – Young Residence, Arizona

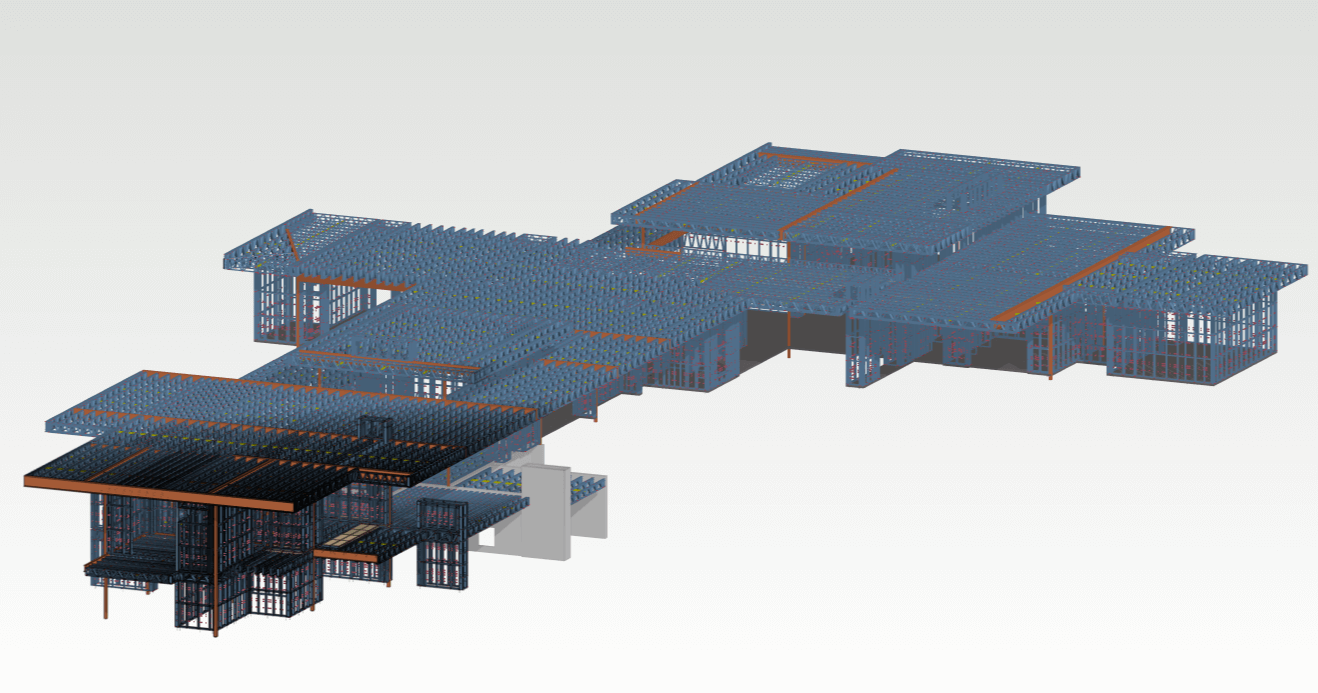

UBC BIM Services thrives on solving complex structural challenges, and the Young Residence in Arizona was no exception. Spanning over 18,000 sq. ft., this hybrid two-story residence combined light gauge steel framing with hot-rolled steel, red iron and timber elements to achieve architectural intent and structural integrity. This was a test of engineering coordination, digital precision and streamlined automation.

- Case Study

- Clients: UBC BIM Services, Howick, Revolution Steel, Arcadia Builders

- Country: USA

- Date: December 2025

- Type: Steel Framing / Prefabrication

Turning BIM into machine ready data

The project’s success lay in UBC’s BIM expertise supported by Vertex BD’s intelligent design software and Howick’s precise roll-forming technology.

Leveraging Vertex BD’s direct integration with Howick FRAMA™ roll-forming machines, UBC BIM used Vertex BD’s software to generate machine‑ready data without any additional file conversion or loss of accuracy.

This digital connection reduced the risk of translation errors and accelerated production while ensuring studs, tracks, and trusses aligned with the design intent.

Rapid fabrication through automation

For this project, fabrication was carried out by Revolution Steel, a Howick customer known for precision framing solutions. Using a Howick FRAMA™ 3200 roll-forming machine, Revolution Steel translated machine-ready data directly from the Vertex BD software to produce framing components with exceptional accuracy.

This seamless digital-to-physical connection was made possible by Howick’s open language control system, which allows direct data transfer from the BIM model to the machine without the need for file conversions or manual re-entry. The result? Steel profiles fabricated with accuracy down to 0.5mm, ensuring each stud and track precisely matched the original shop drawings.

General Contractor Arcadia Builders, client of UBC BIM Services, managed the onsite execution, benefiting from a fabrication process that was both fast and highly coordinated. Together, this ecosystem of design, detailing and automation delivered a high performance hybrid structure with minimal error, reduced waste, and improved build efficiency.

Delivering results that matter

Design and detailing for this large hybrid structure was completed in 25 working days, with the client commending UBC BIM Services for their attention to detail and professionalism.

By smartly integrating Vertex BD’s intelligent software with Howick’s roll-forming technology, UBC BIM Services created a truly seamless digital-to-physical workflow, that reduced both time and labour while enhancing precision and project control.

Project summary

- Project: Young Residence, Arizona, USA – 18,315 sq. ft.

- Challenge: Hybrid structure with large span trusses and mixed materials

- Solution: Integrated digital detailing-to-fabrication workflow using Vertex BD automated BIM software and Howick’s FRAMA™ roll-forming technology

- Machine used: Howick FRAMA™ 3200

Result

- Design and detailing services completed in 25 working days

- High-precision combination of hybrid structure coordinated from a single model

- Framing exactly matched BIM model without file conversions or data re-entry

About the partners

UBC BIM Services

UBC BIM Services provides high-level BIM modelling, detailing, and coordination services for the AEC industry. With over 75 engineers, modelers and detailers, UBC is a one stop shop for light gauge steel and timber framed structures.

Howick

Howick is a pioneer in the technology of precision light steel roll-forming machines. For nearly 50 years, their commitment to innovation in Cold Formed Steel (also known as Light Gauge Steel), precision manufacturing, uncompromising quality and exemplary customer service has defined the Howick way. This commitment underpins the competitive advantage enjoyed by its customers.

Revolution Steel

Revolution Steel leverages advanced technology and precision fabrication to deliver steel framing solutions with unmatched accuracy and efficiency. Their vertically integrated process, from robotic site layout and 3D scanning to digitally engineered panels, ensures homes and buildings are framed to exacting standards with minimal waste and faster timelines.

Related stories

Vertex BD Supports MYT Framing Solutions in Delivering Coordinated LGS Projects Across South Australia

MYT Framing Solutions has developed a digitally driven approach to light gauge steel (LGS) framing that combines coordinated design, controlled manufacturing and detailed installation support. Central to this is Vertex BD, the platform MYT uses to model, coordinate and deliver fabrication-ready output for a wide range of residential and commercial projects.

Building Better with Steel: Sweelco Is Using Tech and Steel to Revolutionize Construction

By using advanced BIM software like Vertex BD, Sweelco enhances the construction experience for its clients by making the design process more precise and efficient, ensuring high-quality results from design to production.

MYT Framing Solutions

MYT Framing Solutions achieves seamless collaboration and accelerated project completion with Vertex BD software. By supplying 100 tonnes of steel frames for the Norwood mixed development project, the company demonstrates its expertise in handling complex designs and delivering lightweight frames for large-scale projects.