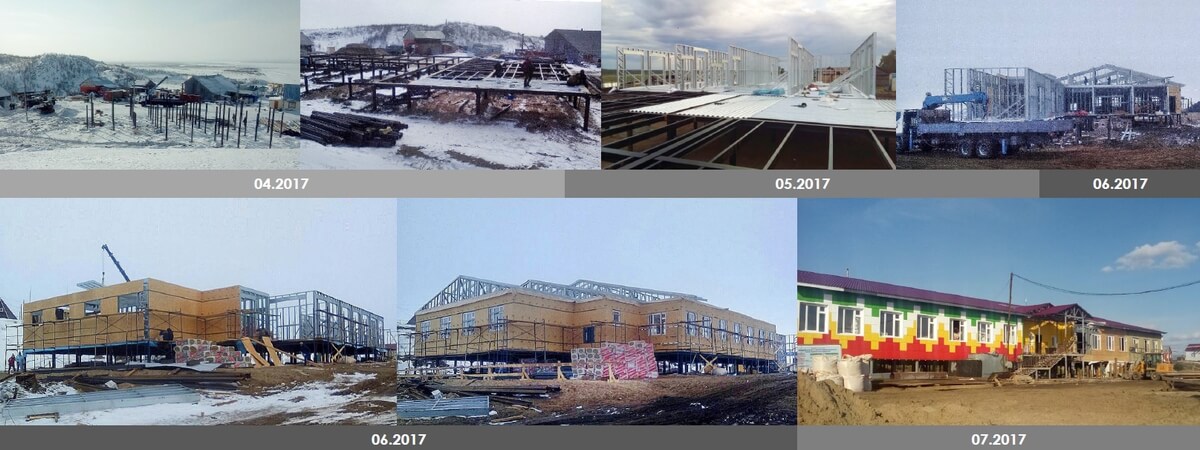

Award winning project completed two months ahead of schedule in harsh Siberian conditions.

Siberia typically has short summers and long, brutally cold winters. On the north coast, north of the Arctic Circle, there is a very short, about one-month long summer. A Siberian construction company, Adgesia Metal Constructions, won the Russian National Steel Force award for the Saskylach Kindergarten project that was built in 6 months in the harsh Siberian climate.

- Case Study

- Client: Adgesia Metal Constructions LLC

- Date: March 2020

- Country: Russia

- Type: Commercial Construction, Steel Framing

Adgesia Metal Constructions

Project Information

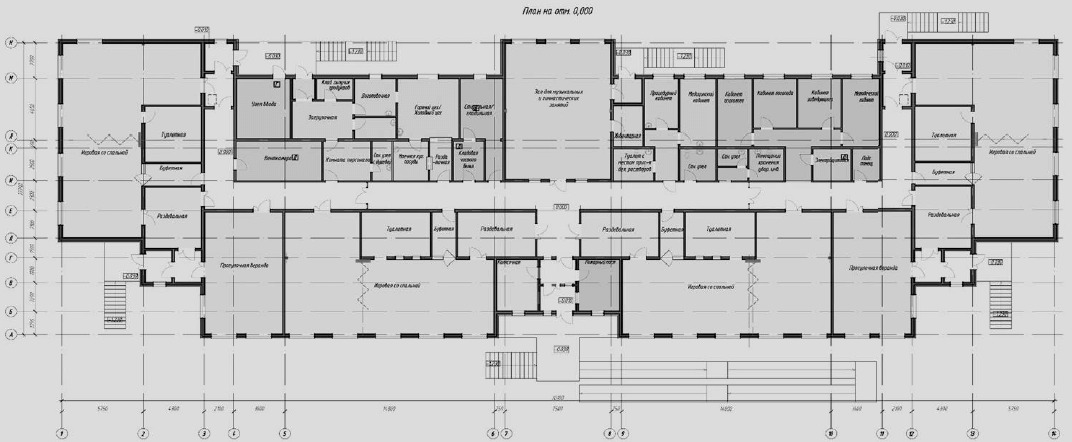

Project: Kindergarten. Four equipped playgrounds, classrooms and offices, fully equipped kitchen and dining room, fully equipped rooms for medical, speech therapist and psychologist.

Capacity: 98 children.

General Designer and Builder: Adgesia Metal Constructions LLC.

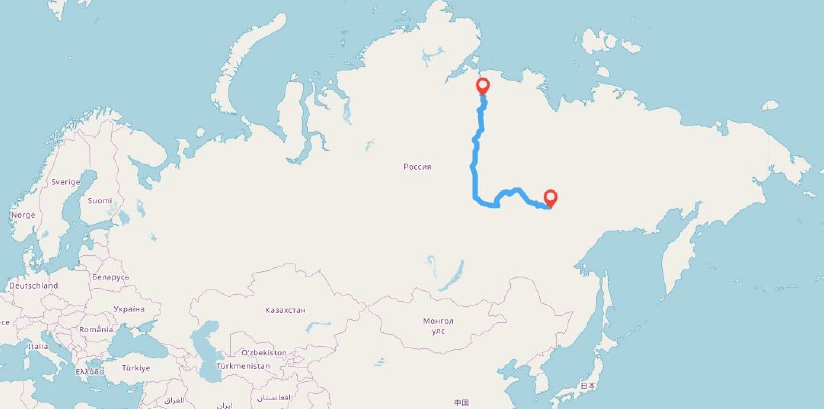

Location: Siberia Saskylach, North Yakutia, Russia.

The distance from the production facility to the construction site: 2,700 km (1,677 miles).

Total Building Area: 1,303 m² (14,025 ft2).

Construction started: April 2017.

Construction finished: September 2017.

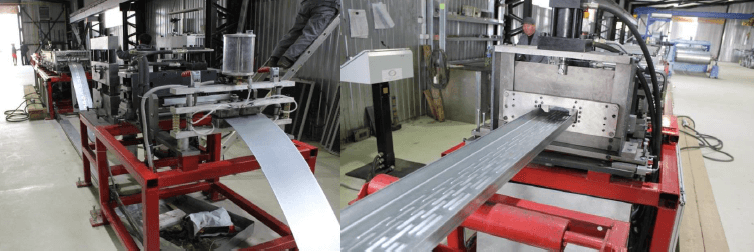

Cold-Formed Steel Technology

Adgesia Metal Constructions’ mission is to develop and use Cold-Formed Steel (CFS) technology (also called Light Gauge Steel or LGS) as a prior method of construction in the challenging Siberian climate. 10 years of experience have proved the critical advantages of the CFS technology in such conditions:

1. Low weight of the buildings

- reducing cost of foundation structures.

- reducing transportation costs.

2. The absence of “wet construction” processes build any time of the year.

- easy installation.

- minimal need of transporting construction equipment to the construction site (in particular, lifting equipment is not required for the installation of CFS structures).

- reducing the cost of construction work (assembly, finishing work).

- reduction of construction time.

3. Reliability of steel framing

Durability and strength characteristics of frame elements are suitable for buildings and structures in various environments.

4. Carry seismic loads

Buildings from CFS have great seismic stability (up to level 9), due to the low specific gravity and structural features of the framing.

5. Architectural diversity

Ability to create almost any architectural form.

Improving Thermal Performance

In 2014-2016, tests were carried out on typical CFS structures of Adgesia Metal Constructions. Wall panel samples were designed and tested in an expert testing laboratory in Yakutsk, meeting the modern requirements of the heat-shielding properties of building envelopes for the Far North.

The results were introduced into the design and construction methods of modern CFS buildings, allowing the expansion of Cold-Formed Steel technologies in the construction industry.

As a result of research and development, the main technical solutions were developed:

- Adding new special external sheet layers and materials outside of framing to ensure air tightness of the entire building.

- An increase in the external insulation layers with a decrease in insulation inside the building framing, that lead to overall increase in thermal performance.

- New thermal breaks in the connections of wall framing structures and layers to the foundation.

3X Faster and 2X Cheaper Construction with Steel

Adgesia Metal Constructions collected data from different CFS and brick masonry construction projects in the Arctic regions of Yakutia and the results are summarized in tables:

| Building Characteristics | CFS building | Brick Building | Effect |

| Building Weight, kg/ m² | 390 | 4000 | 10.2 times lighter |

| Construction Time, months | 6 | 18 | 3 times faster |

| Costs per m² | CFS building, EUR | Brick Building, EUR | Effect |

| Building Costs | 690 | 793 | 1.15 times cheaper |

| Transportation | 235 | 1367 | 5.83 times cheaper |

| Total Costs | 925 | 2160 | 2.34 times cheaper |

Steel Force Award

The winners of the Russian National Steel Force award at the Metal Expo event in Moscow. In the middle, CEO of Adgesia Metal Constructions LLC, Egor Sivtsev, and on the right Chief Engineer Alexey Pestryakov.

Related Stories

Building Better with Steel: Sweelco Is Using Tech and Steel to Revolutionize Construction

By using advanced BIM software like Vertex BD, Sweelco enhances the construction experience for its clients by making the design process more precise and efficient, ensuring high-quality results from design to production.

MYT Framing Solutions

MYT Framing Solutions achieves seamless collaboration and accelerated project completion with Vertex BD software. By supplying 100 tonnes of steel frames for the Norwood mixed development project, the company demonstrates its expertise in handling complex designs and delivering lightweight frames for large-scale projects.

Steel Frames Direct

Steel Frames Direct was established in 2020 to provide light gauge steel framing solutions for residential, commercial and light industrial building projects. The company’s focus on customer satisfaction, and use of Vertex for efficient collaboration and communication sets them apart from their competitors.