Positive results for the end customer and the bottom line through optimised design process

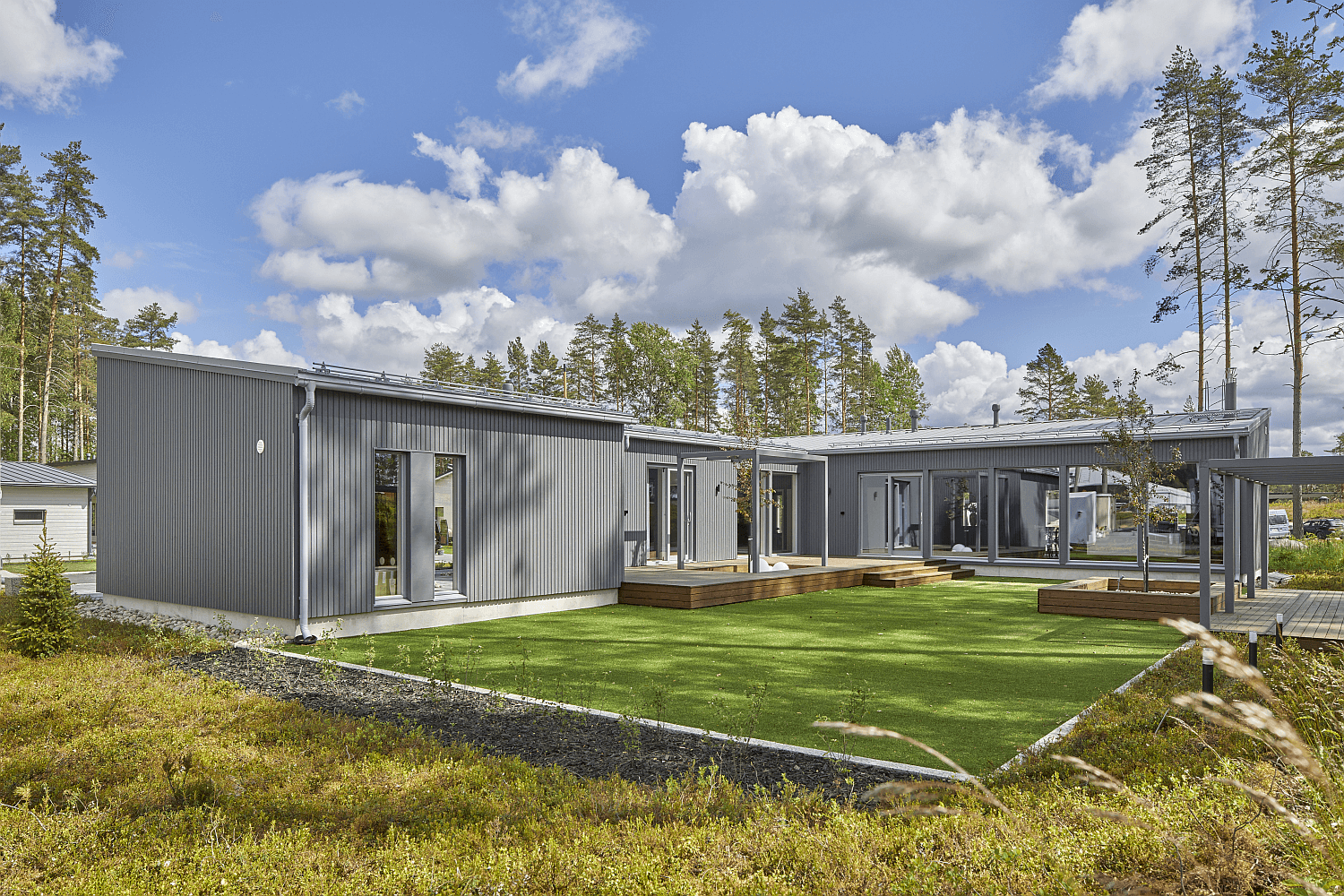

DEN Finland Oy offers turn-key houses and business premises as well as construction services to private individuals and companies. Today houses and business premises are mainly custom-designed according to the client’s wishes. Individuality is always a challenge for design, production and profitability in construction, but DEN Finland and one of its brands, Designtalo, have decades of experience of profitable construction of private homes.

- Case Study

- Client: Den Finland

- Date: March 2019

- Country: Finland

- Type: Residential Construction, Wood Framing

DEN Finland

According to Petteri Typpö, Design Manager at DEN Finland’s construction operations, with good design, standardized approaches and good design software, you can build custom-homes cost-effectively and appealing from both the client’s and company’s perspective.

“Customisation has a direct impact on the design process. It slows down the design work many times over compared to making small, predefined standard changes to a standard house model. However, we can produce customised homes smartly, even those designed by external architects, as the design process, details and design components are largely standardized. Using effective design software and a product data management system we can avoid problems in the later stages of the process and maintain good quality throughout the entire production and construction process of the house,” explains Mr Typpö.

Cost-effective and customised-home through good design

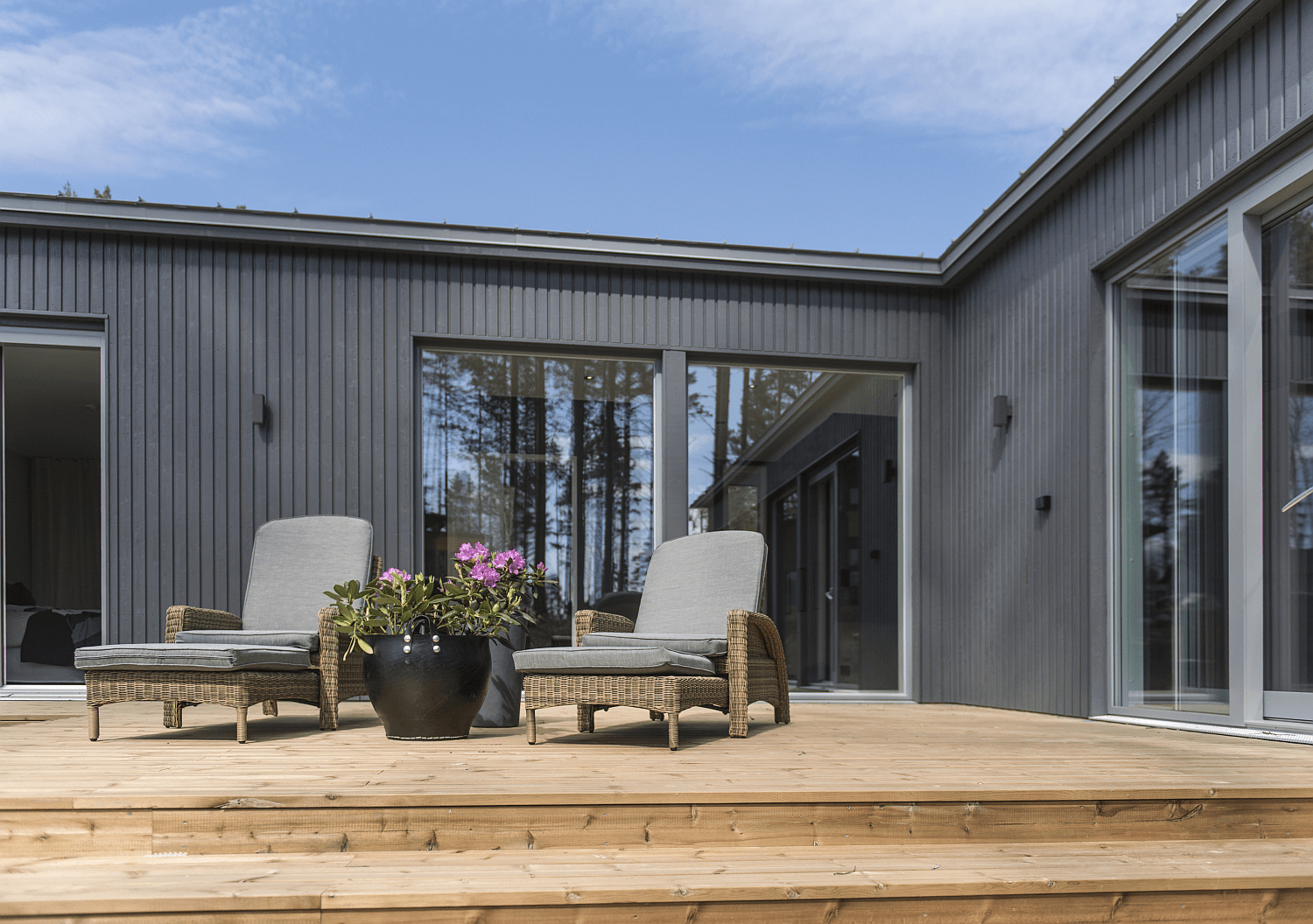

Those planning their dream house come to Designtalo looking for a way to get their customised home built easily. “With all the regulations, building your own home has become so difficult that if you are on your own and have no training in this field it is not worth starting; and not many do start. What people want is as ready as possible, with as little effort as possible, but customised. Designtalo offers genuinely turn-key, unique houses and is one of the rare suppliers of such houses in Finland. They can even have the garden landscaped and ready, if they choose so.” Mr Typpö points out.

The Vertex design software and product data management system benefits the end customer too. From the smart 3D models, it is easy to produce pictures and prices for marketing purposes on the web and in brochures. When a homebuilder comes to meet the sales staff not knowing precisely what kind of home they want, the sales people can browse with the customer through the selection of models to find suitable options. “The customer finds the best solution usually by combining models and then we can quickly produce outline drawings from them and also give them a price. When the final 3D model and its plans are ready, we can show the customer even small details from the pictures if they want, such as the window frames or even the location of electrical sockets,” explains the Design Manager.

Design impacts on overall costs and profitability

DEN Finland has solid experience of using Vertex, as it was selected years back by Designtalo to optimise the design process and production. The company has been an exception in the private home construction sector and still is – it performs well year after year and operates profitably. One of the bases of this profitability is sensible design and standardisation. From the beginning, the company has invested in good design tools, high quality of design and standardisation of design and production.

Petteri Typpö points out: “When the design work is done properly from the beginning, there is no need to correct mistakes during production or, even worse, on site. The 3D design is the most important part of the design software for us, as we are able to use it to check the designs before production and foundation works. We can see straight from the plans if the foundations are not suitable for the house. We do not need to design every detail from scratch because they are completed in the software as a standard for all the designers and for production.”

The company also uses the Vertex DesignStream product data management system which is used to store all the design projects and the documents they generate with their revised versions. “DesignStream enables our designers all over Finland to always have access to the latest design data. Each detail and structure does not have to be designed multiple times over and useless double work is avoided.” sums up the Design Manager.

The quality of the design is based on such architectural planning that satisfies the customer’s wishes while at the same time taking into account how the limitations and standards affect to the house production. At present, DEN Finland utilises Vertex BD building design software. Vertex BD design software automatically produces architectural plans and shop drawings needed for the factory and the construction site from the 3D model. The documents are stored in the Vertex DesignStream data management system where they can be accessed by all parties who need them in real time, 24 hours a day.

Important to get help quickly

There are already 50 Vertex users in the Group, but the use of the software is expanding even further. The production software for the Group’s log house factory Finnlamelli will switch to utilise the Vertex 3D model data and in future, the log diagrams will be produced in the same way as the structural drawings at Designtalo. Precise log diagrams reduce mistakes both in the log house production and on site.

According to the Design Manager, the feedback from the Vertex users has been positive: “The best thing in the design software is the 3D design and the fact that it is available in the local language. The best thing about collaboration is that we can always get help quickly from Vertex no matter what the issue is or what time it crops up.”

“We work very closely with DEN Finland, accelerating their order to delivery process by utilising Vertex software solutions from design to production. By using smart 3D models as a data bank of the whole process, the data produced in the proposal and permit approval phases can be used in the following phases such as generating manufacturing drawings for the panels, as well as the NC files needed for manufacturing equipment, directly from the 3D model. This eliminates human error, and so buildings are designed and manufactured faster.” explains Vertex’s Santeri Pyhäniemi.

—

DEN Group is one of Finland’s leading manufacturers of turn-key homes and functional business premises as well as a provider of construction services. At the beginning of 2019, the Group employed almost 550 people. The DEN Group comprises Designtalo the pioneer of turn-key and ready-to-move-into homes, the Ainoakoti brand, owned jointly with Kesko, the log house manufacturer Finnlamelli, Talliosake, which provides buildings for work and leisure, the civil engineering company Pohjan Teko, the civil works, foundations and building construction design company PohjanGeo and the HVAC solutions producer Designtalo Tekniikka. Take a closer look at the Group at this address: http://www.den.fi/en.

Related Stories

Hawo

Hawo are a manufacturer and supplier of high-quality tiny homes and holiday houses. They are forerunners in prefabrication, basing their production in a self-developed concept of prefabricated housing.

Celt

When the plans are finished in advance, manufacturing the CLT panels and assembling the components is much more cost-efficient and the entire project schedule is significantly shorter. Prefabricated construction with CLT panels is quicker, more efficient and is carried out in controlled indoor conditions from start to finish.

Planimo

A uniquely designed, industrially manufactured and cost-effective home – reality or fantasy?