Sage Building Components’ Pre-Cut Process Decreases Framing Time by 25%

As a long-time framing contractor, Sage Building Components (SBC) understands the importance of traditional craftsmanship — and the innovations needed to be as efficient as possible in today’s construction industry.

- Case Study

- Client: Sage Building Components

- Date: November 2019

- Country: USA

- Type: Commercial & Residential Construction, Wood Framing

Sage Building Components

Sage Building Components is located in Ames, Iowa, USA — a college town with a population that fluctuates with the seasons. “For us, it really started with a labor issue,” says Andrew Sage, the company’s president. “We were spending a lot of time and money training people that would eventually move away, so we were losing all that skill we had invested in. As a solution to the problem, we came up with our pre-cut process.”

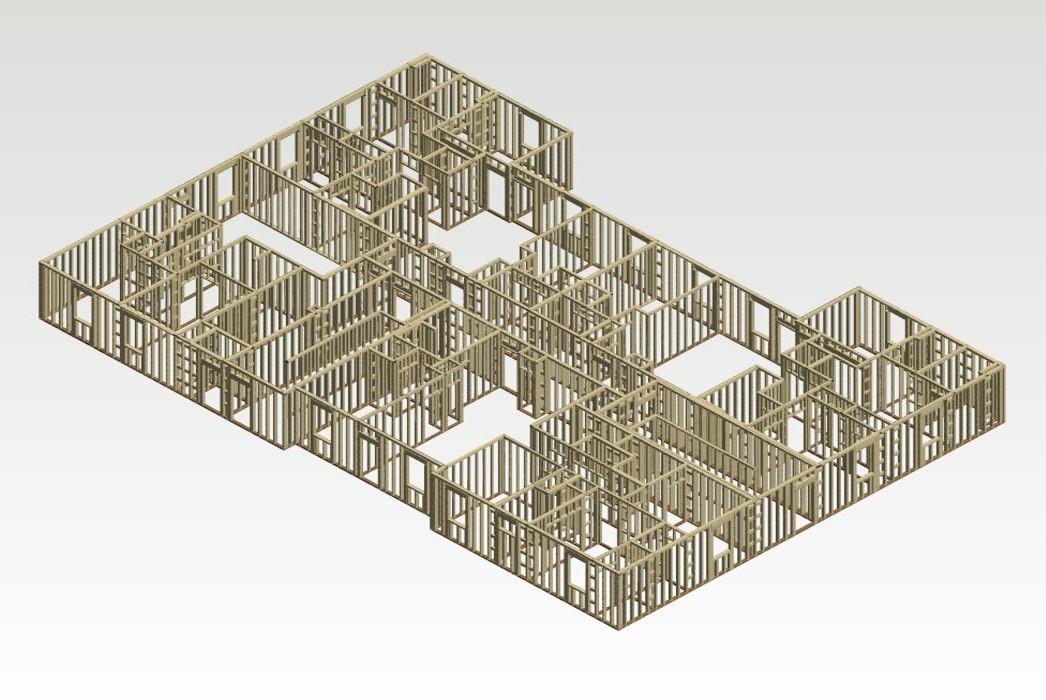

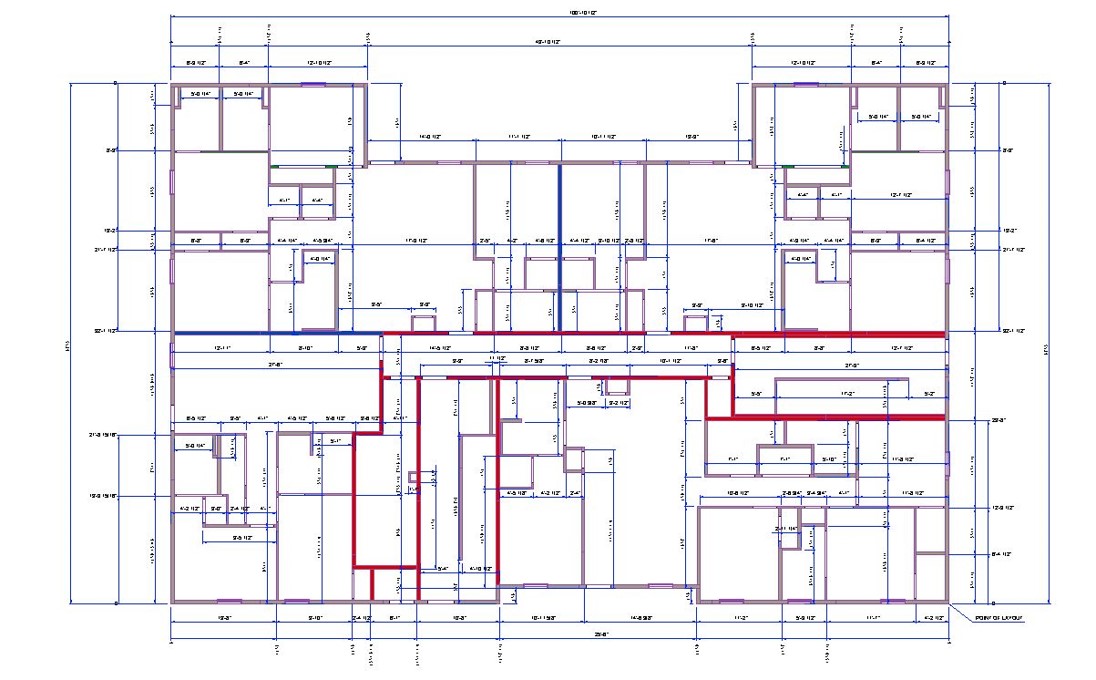

This process, now known as Sage Cut Components, is a method where all the framing elements for a stick-built project are pre-cut, labeled, and strategically bundled before hitting the job site — decreasing framing time by 25% or more.

“To get started, we actually spent a lot of time looking at LEGOs; we liked how they were packaged and indexed in steps,” Sage explains. “We knew if we could cut our pieces with that same accuracy, we could reduce the framing down to simple assembly to minimize labor needs in the field and save time and money as well.”

BIM Software Delivers One-of-a-Kind Benefits

To cut and label their packages with exact precision, SBC decided to utilize equipment originally designed and built for the cabinet industry. It was essential that this equipment was able to sync with the modeling software they chose to design their projects, and they quickly recognized that Vertex BD’s adaptability and overall innovation could deliver the level of quality they were looking for.

“Without that ability to accurately model for every fixture and every little building element, you’d just be guessing. With Vertex BD, we’re confident that what we’re doing is 100% correct,” Sage explains. “For example, I don’t know if there’s any other product out there with the precision to show you exactly how each drain pipe will fit into every tub within a building. Vertex BD can do that.”

Two of the key benefits of working with Vertex BD’s professional BIM software are the capability to use it for any type of project at any size, and the flexibility to combine Vertex models with elements from other design software. Sage says, “With Vertex BD, we can import and overlay models from our vendors, which is a huge advantage when you’re working to create the most accurate drawings possible to minimize time and confusion in the field.”

To take this ease of access one step further, Vertex has recently released its Vertex Showroom — a web-based application where you can upload your digital model to be shared with anyone, from any location.

“All of our foremen have tablets, so when they’re in the field they can pull up the model and see exactly how everything is going to fit together and interact. Everything from the steel connections to the stick framing can be modeled,” Sage explains.

According to Sage, this level of accessibility is significant, because with most other software, you have to download their specific viewing app. With the Vertex Showroom, you can simply log on to the web and see every model your company has ever designed. You can also see the building stats for every item within a structure. Click on a door, for example, to make sure everything is labeled correctly and you’re choosing the right one for that specific location — a huge benefit that minimizes mistakes and extra costs.

“This is the way we communicate now,” Sage says. “If the crew has a question, the foreman can call when he’s in the digital model. Because we’re all looking at the exact same thing, everyone gets their answers more quickly and there’s less confusion.”

Smart Design, Increased Efficiency

For Sage Building Components, the ultimate goal is to create the most efficient hybrid framing system utilizing both on-site and offsite technologies. Ambitious to be sure, but with Vertex BD’s innovative modeling technology paired with the state-of-the-art precision tools for cutting and labeling every piece, they are on the path to accomplish that goal.

“Regardless of the project type, we strive to complete our jobs faster, with higher quality standards, and with smaller crews,” says Sage. He adds that, thanks to a 15% reduction in material waste, they’re seeing significant financial advantages to the process.

“The idea of off-site construction may be growing in popularity, but we can’t get around the fact that we’re always going to have to do most of the building at the job site. So, instead of assembling most of the building in a factory and then paying to ship it, why not build better efficiency into the field?” remarks Sage. “At Sage Building Components, we’re developing a process that’s pushing to create that increased efficiency.”

Related Stories

Helena Lidelöw: Steering VBC to global success with Vertex BD software

VBC grows with a core strategy centred on customisation and flexibility in Vertex BD, guided by Helena Lidelöw.

The three questions that shaped Ecohuis success in modular

Ecohuis, the leader in the Belgian modular home market, has shaped their success by focusing on three critical questions.

Leveraging automation: Vertex BD’s, Randek’s and Arcabo’s partnership offers unparalleled benefits

Arcabo has revolutionized home-building through strategic partnerships with Vertex Systems and Randek, leveraging automation to offer high-quality buildings at various price points.