Customer Case Studies

Learn how our clients are saving time and money with Vertex BD.

Categories: Latest Stories | Steel Framing | Wood Framing | Manufacturing Equipment

Latest Stories

Acetra ZWOLLE Project: Part 3

Working together with the entire design and construction team, Acetra advises the assembly of the three-story CLT structure to completion.

Acetra ZWOLLE Project: Part 2

With the help of BIM technology, the Acetra team works together with architects and contractors to create a modern design that blends seamlessly with its traditional surroundings.

Hoivarakentajat

Log as a material is sense-friendly, calming and natural. It is acoustically pleasant, balances moisture in indoor air, and its construction physics are well suited for Scandinavian climate. Timber structures enable carbon-negative construction.

ACETRA: the Zwolle Project Part 1

In construction, challenges come with the territory. But for some projects, like this three-story residential/commercial CLT structure in the Netherlands, the complications are what take the design to the next level.

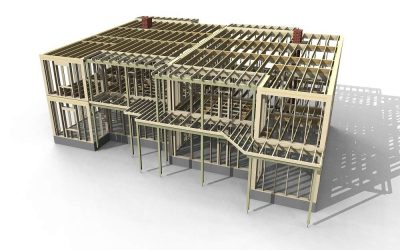

Service Offsite Solutions

Service Offsite Solutions is changing the way residential framing is done by delivering a framed house, dried-in, in less than half the time it takes for traditional stick framing.

UBC

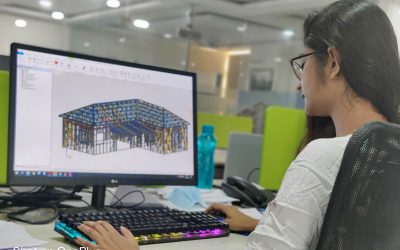

How Cold-Formed Steel + BIM Software is Changing Construction in India?

Celt

When the plans are finished in advance, manufacturing the CLT panels and assembling the components is much more cost-efficient and the entire project schedule is significantly shorter. Prefabricated construction with CLT panels is quicker, more efficient and is carried out in controlled indoor conditions from start to finish.

Design Service JK

Factory-based production of wooden houses is not unusual anymore. Nowadays, a high priority is given to the quality of indoor air and protecting the structures from getting wet during construction is a must. Cross Laminated Timber panels are manufactured indoors which also reduces the amount of on-site work.

LapWall

Making an architect’s vision a reality often requires a lot of work, strong professional expertise, and creative problem-solving. LapWall, who implemented the roof structure at Helsinki-Vantaa airport’s terminal 2, drew from all of these. As an extra challenge, the installation contract was carried out at night when the site was otherwise quiet.

Steel Framing

BW Industries

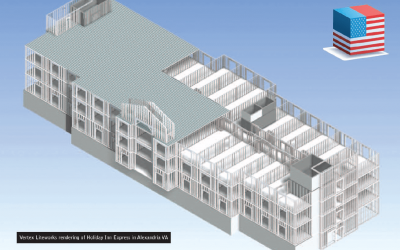

Site teams can interrogate a 3D model as the structure is erected. This not only reduces calls from site to the design office but also speeds up the erection process, as site operators are able to easily review the model in 3D on site.

ThermaSteel

The high-level and customizable integration of design software and manufacturing hardware allows Thermasteel to accelerate their processes and minimize mistakes on all stages.

ABT Construction

The mix of innovative off-site and more traditional on-site methodology enables ABT to reduce costs through increased speed of construction.

Stoddart Steel House Frames

Large projects are now easier to produce and manage. What would have taken 2–3 hours to do in the previous system has now been reduced to a 15-minute job.

Light Gauge Steel Framing

Light Gauge Steel Framing’s success is based on attention to detail and the ability to respond to our customers’ requests and requirements quickly.

Mekos Stroy

The company now completes design projects effectively and with maximum accuracy in the Russian low-rise construction market.

Queensland Steel House Frames

Learn how digital automation stops QLD Steel House Frames from making mistakes and having things sent to the site incorrectly.

Borabela

Converting smart architectural design into an optimal construction process reduces the costs of logistics, building materials and construction time.

Newcom Mining Services

Learn about a successful construction project in the Gobi desert where the climate conditions are extreme and the rough terrain provides many challenges.

Elements Europe

“Vertex play a big part in our process, and we are always looking to improve productivity. Working very closely with Vertex, we are achieving this.”

B&J Building Consultants and Steel Supplies

“The time taken to design a typical dwelling has been reduced by over 50% and design issues have been reduced by around 90%.”

Panel Systems

“The information we get from Vertex BD is clear, concise and understandable. 99.9% of what we put out fits without any site modification.”

Wood Framing

LapWall

Making an architect’s vision a reality often requires a lot of work, strong professional expertise, and creative problem-solving. LapWall, who implemented the roof structure at Helsinki-Vantaa airport’s terminal 2, drew from all of these. As an extra challenge, the installation contract was carried out at night when the site was otherwise quiet.

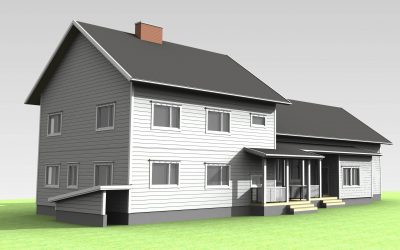

Puukoti Group

High-quality residential construction requires expertise that stems from long-term experience and a healthy respect for tradition. Meeting the increased demands of construction and housing require modern working methods, from design to manufacturing, and an increasing number of homes are being manufactured in factory conditions.

POOK Architects

A complex and demanding commercial building project with so many rounds of comments and approvals would never be implemented without BIM.

Planimo

A uniquely designed, industrially manufactured and cost-effective home – reality or fantasy?

Ursem

The tallest modular building in the Netherlands was manufactured in just 5 months, with only 3.5 months spent on-site. From design to completion, the entire project took only two years.

Sage Building Components

Sage Cut Components is a method where all the framing elements for a stick-built project are pre-cut, labeled, and strategically bundled before hitting the job site — decreasing framing time by 25% or more.

Machiels Building Solutions

Learn how Machiels built 400 homes in 200 working days using prefabricated construction methods to create the structures as efficiently as possible.

KVR-Engineers

Learn how faster design process has allowed KVR-Engineers to grow, taking on more clients and providing faster turnaround times for existing clients.

Statistics from 35 Framing Projects

Statistics from 35 projects in Norway show that it is possible to complete almost any framing design project in an average of 16 hours or about two working days.

ACE Arheget

Customer satisfaction has increased through having fewer problems at the site, and being able to offer more precise end results to the customer.

DEN Finland

From the beginning, Den Finland has invested in standardisation of design and production. The company performs well year after year and operates profitably.

The Timber Frame Company

“Vertex BD software enables us to deliver a project from design to build in a simple, time efficient and most cost effective way.”

Manufacturing Equipment

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.